Unprotected cross-connections are health hazards and have the potential to introduce contamination into drinking water sources. Noncommunity water systems cannot have, create or maintain unprotected cross-connections.

What is a cross-connection?

A cross-connection is an actual or potential link between a source of contamination and a drinking water supply. Cross-connections are fixtures with direct connections or submerged inlets. Common examples of fixtures with direct connections include boiler systems, dishwashers, fire sprinkler systems, laboratory equipment and swimming pools. Common examples of fixtures with submerged inlets include lawn sprinklers, utility sinks, drinking fountains, floor drains and garden hoses.

What is backflow?

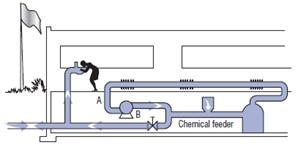

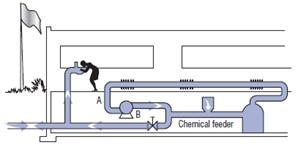

Backflow is the unwanted reversal of flow in a water distribution system. Backflow occurs due to backpressure or backsiphonage and allows non-potable substances to enter a water system through an unprotected cross-connection.

Backpressure occurs when the pressure in a building’s plumbing exceeds the pressure in the water distribution system. For example, if the pressure in a boiler system exceeds the pressure in the water supply line, liquid will move from the boiler into the water supply.

Backsiphonage occurs when there is a partial vacuum (negative pressure) in a water supply system, drawing liquid from the non-potable source into the water

distribution system. For example, during a lower pressure event, a tub with a submerged inlet can act as siphon pulling non-potable water through the building’s plumbing and into the water supply.

Are noncommunity water systems required to have a backflow prevention program?

Noncommunity water systems are not required to have a backflow and cross-connection prevention program like community water systems. However, noncommunity water systems cannot have, create or maintain unprotected cross-connections.

What are the regulatory requirements for water systems using groundwater?

The Missouri Department of Natural Resources Groundwater Rule, 10 CSR 60-4.025, defines a Significant Deficiency as a defect in design, operation or maintenance or a failure or malfunction of the sources, treatment, storage or distribution system that has caused or has the potential to cause the introduction of contamination into the water delivered to customers. An unprotected cross-connection has the potential to allow contamination into the water system. The existence of a known unprotected cross-connection is considered a significant deficiency. The Groundwater Rule applies to all community and noncommunity water systems using groundwater (wells) as a source.

What are the design guide requirements for a new noncommunity water system?

The department’s “1982 Standards for Noncommunity Public Water Supplies” contains design guide requirements for new noncommunity water systems. Section 6.8, titled Cross-Connections and Interconnections, states, “There shall be no connection between the distribution system and any pipes, pumps, hydrants, or tanks whereby unsafe water or other contaminating materials may be discharged or drawn into the system”. In order to meet this requirement, a noncommunity water system shall either (1) install a backflow prevention assembly or (2) remove the cross-connection to eliminate the hazard. The department recommends backflow prevention assemblies be installed in accordance with 10 CSR 60-11, titled Backflow Prevention, which outlines potential hazard classifications.

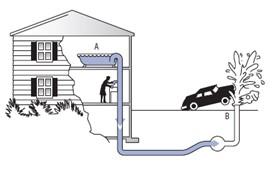

What is a backflow prevention assembly?

A backflow prevention assembly is a means or mechanism to prevent backflow. The department recognizes three types of backflow prevention assemblies: air gaps, reduced pressure principle assemblies (RPZ) and double check valve assemblies. An air gap is a physical separation between the water supply and a building’s internal piping system. The height of the faucet above the rim of the sink is an air-gap. A reduced pressure principle assembly is the highest level of mechanical backflow protection. A double check valve assembly is for low hazard protection only.

The department recommends backflow prevention assemblies installed at noncommunity water systems be approved by the Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California or the American Society of Sanitary Engineering. Information about approved assemblies is available on the department’s Backflow Prevention webpage.

Does my backflow prevention assembly need to be tested?The department recommends backflow prevention assemblies at noncommunity water systems be tested upon installation and then annually thereafter by a certified backflow prevention tester, or in accordance with the manufacturer’s recommendations. A list of certified backflow testers in your area is available on the department’s Backflow Prevention webpage.

Does the backflow prevention assembly protect my entire facility?

No. The department uses the containment approach. This protects the well from contamination, but cross-connections in your plumbing can allow contaminants to backflow to drinking water taps in your building or at your facility. To protect potable water within a building or facility from potential hazards requires a backflow prevention assembly just prior to each known hazard, such as on the line to a fire sprinkler system, an irrigation sprinkler system or a septic dump station at an RV park or campground. This type of prevention applied within a facility to protect drinking water plumbing from non-potable sources or contaminants is called isolation.

Your local plumbing code may require isolation backflow prevention. If you have questions about your local plumbing code, please contact your city and/or county for more information. To help protect public health, all facilities should consider implementing isolation backflow prevention.

Who do I contact if I need help finding cross-connections at my facility?

Contact a certified backflow prevention tester to have a survey completed of your facility. To find a certified backflow tester in your area, please visit the department’s webpage or contact your Regional Office for more information at:

Central Field Operations 573-522-3322

Northeast Region Office 660-385-8000

Southwest Region Office 417-891-4300

Southeast Region Office 573-840-9750

Kansas City Region Office 816-251-0700

St. Louis Region Office 314-416-2960